what drive units are being used in 2018 to replace bad drive units in model s

Electric Motor Reset Push button

Electric Motor Reset Push button

How to Reset, Diagnose, or Set up the Thermal Overload Switch

- Postal service a QUESTION or Annotate On electric motor issues, motor overheating, thermal overload protection devices

InspectAPedia tolerates no conflicts of interest. Nosotros have no relationship with advertisers, products, or services discussed at this website.

Electrical motor thermal overload switch guide:

This article describes how to observe and reset the thermal overload push button on an electrical motor and we give suggestions for repairing hard-starting or non-starting electric motors such as on air conditioning condenser fans and blower fans.

We describe where to find reset switch on well-nigh electrical motors.

We explicate nearly automatic thermal overload switches on motors - switches that reset themselves when the motor cools downwardly. And we describe what can go wrong with automated thermal overload switches on electrical motors. Nosotros include tips for diagnosing electric motors that keep having thermal overload symptoms.

We too provide an Commodity Index for this topic, or you lot tin can endeavour the folio top or bottom SEARCH BOX as a quick way to find information you demand.

How to Find and Reset a Heating System or Air Conditioning Electric Motor

How to find and reset the thermal overload switch found on many electric motors. Electric motor troubleshooting guide for electrical motors that overheat.

How to find and reset the thermal overload switch found on many electric motors. Electric motor troubleshooting guide for electrical motors that overheat.

Some Electric Motors Include an Automatic Thermal Reset Switch: how to reset the motor switch on water pumps and well pumps - cool-downward period.

Commodity Contents:

- RESET BUTTON, Electrical MOTOR

- FIND the MOTOR RESET Push

- HOW TO RE-SET the OVERLOAD SWITCH

- WHAT the RESET BUTTON LOOKS LIKE

- Automatic THERMAL RESET SWITCHES

- THERMAL OVERLOAD SWITCH REPLACEMENT

Electric motor overload reset buttons - how to find and reset motor overload switches

An electrical motor used in lots of equipment may include overload reset push on the motor body. If the motor is overloaded or if it overheats, this button will popular "out" indicating that an internal electric safety device has tripped,shutting the motor off.

Once the motor has cooled sufficiently it tin exist re-started, usually by pushing the popped-out reset switch back down.

If the motor turns off once again on re-ready you should not keep running information technology equally it may exist damaged and the system may be dangerous.

The page top photograph was taken of of an oil burner electric motor not an air conditioning blower fan motor or pump motor, merely you'll see that all of these electric motors look a lot akin. Sometimes the reset button on an electrical motor is hard to discover, and sometimes at that place is no reset button!. But this photo shows the red reset button most clearly.

Tips for Finding the Motor Reset Button

Find the electric motor that operates the device that has been close downwards. For example on a warm air heating arrangement or primal air conditioning system look in the air handler/blower compartment.

On the blower motor itself, look for a red or yellow button which is ordinarily flat with the motor surface but which volition pop up to show that the motor has been shut off by its internal overload protection circuit.

If the installer rotated the motor so that the button is facing away from you and impossible to see, feel effectually on the bottom and dorsum side of the motor for the button's presence. Especially if the motor's internal protection has tripped, it should be easy to feel the button since it'll be sticking up nigh 1/two".

When and How to Reset the Electric Motor on a Heating Blower, Air Conditioner Blower, or Water Pump

When the air conditioner fan or blower motor has cooled sufficiently this button can usually be simply pressed back downward to "reset" the switch. If the motor overload switch won't reset (stay depressed) either the motor is still too hot (wait) or there is another failure that needs diagnosis.

Sometimes the reset push is present simply hard to find, depending on the position in which the motor was bolted in identify.

What the Reset Push Looks Like When it has Not Tripped

You can see that in this picture the button is flush with the motor surface. Sometimes these buttons are hard to detect just they are commonly nowadays on heating and air conditioning system electric motors for fans and blowers.

Electric Motors Using an Automatic Thermal Reset Switch - no reset push button plant

While transmission-reset thermal-overload switches are most common on heating systems such equally oil burners and some fan motors, air conditioner electric motors and compressor motors and submersible well pump motors are an example of motor designs that may be use a thermal overload switch that resets itself automatically when the motor has overheated.

Electric Motor Thermal Overload Switch Trip Temperatures | ||

| Class A electrical motor | 140oC / 284oF | |

| Form B electric motor | 165oC / 329oF | |

Notes to the table in a higher place

The reset temperature is not precisely specified but the automated thermal overload switch volition reset after the motor cools down. [1]

If a well pump motor is overheating for any reason (low voltage, bad starting time/run capacitor, damaged motor, damaged pump impeller parts, loss of water in the well, pump running dry) it may be a model that will turn itself off when also hot. A thermal sensor inside the pump motor housing handles this chore.

With the motor off for a absurd-down flow, the thermal sensor automatically resets and the pump will run again. Typically the "off" time is 15-20 minutes. If the pump on-off activity is erratic or very long, it could be that the trouble is a bad thermal sensor switch.

Annotation that other electric motors may have a thermal reset switch that is mechanical and "pops out" to evidence a red "reset button" that must exist pushed back in manually. If the motor is withal too hot, pushing the push won't work - the button won't stay in.

Electrical Motor Reset Switch Troubleshooting Guide

This first tabular array is for electric motors use in air conditioners, air handlers, blower units, oil burners on boilers, steam boilers, water heaters etc. - HVAC equipment in full general. A 2d section of defects (below) addresses oil burner motors.

Table of Causes of Electric Motor Thermal Overload Switch-OffThings to Check if an Electric Motor Starts simply Overheats and Trips its Reset Button | ||

| Bad line voltage | Apply a VOM to check the voltage level at the pressure control switch | If voltage is likewise low, check voltage at the electric panel and bank check that the proper size wiring was used for the ampacity and length of run and that at that place are no partial shorts or damaged wires or connectors VOLTS MEASUREMENT METHODS |

| Incorrect motor wiring | Check the actual electric wiring confronting the motor wiring diagram or the installation manual for the equipment | Reconnect wiring properly |

| Motor is too hot due to surroundings - inadequate ventilation | Check the air temperature where the motor is located. If the air temperature is over 100 degF, the pump may be too hot and its thermal overload switch tripping because of the environment, not a pump problem. | Install adequate ventilation, or if needed, shading, or relocate the motor/equipment to a cool location |

| Motor subjected to repeated overloading, overheating | A motor subjected to overloading due to very long duty on-cycles may run hot and trip the thermal overload protection device. Eventually the thermal overload switch may itself neglect and the motor will no longer restart nor can you reset the thermal overload switch. | Check the recommended duty cycle and loading on your motor; check likewise for abnormally low voltage levels in the electrical supply. If necessary, supersede the motor with a heavier-duty unit. |

| Motor for a water pump operates too long at low water force per unit area | If the well recovery charge per unit is besides poor and the pump is operating at low water force per unit area, possibly because a tailpiece is installed to prevent air injection and pump burnup, the pump may be overheating. | Install a valve on the water discharge line and reduce water flow to increase h2o pressure within the pump itself. See H2o Force per unit area PROBLEM DIAGNOSIS Table and see WATER PUMP PROTECTION SWITCH |

Notes to the table above

Adapted from diverse sources including Betta-Flo Jet Pump Installation Manual from the National Pump Co. and Adjusted & expanded from Beckett (1989)[1]

Table of Causes of Oil Burner Thermal Overload Switch-Off | ||

| Bad oil pump (fuel unit of measurement) | Oil pump has seized or is binding, overloading the electric motor | Disconnect the coupling between fuel unit and electrical motor and manually turn each shaft to inspect for binding or seizure. Supersede a bad fuel unit. |

| Misaligned components | Connections between the electric motor bulldoze shaft, coupling, and driven parts are loose or improperly mounted | Cheque for misalignment due to loose mounting bolts of motor, blower, fuel unit of measurement; bank check for improper seating of the motor against the oil burner housing such that the motor is askew. Re-mount. |

| Bad electric motor start switch | The electrical motor will overheat if the commencement-switch does non disconnect at the proper or "throwout" rpm. | Meet Electric motor start switch operation |

| Jammed blower wheel | If the oil burner air blower cycle has jammed, perhaps due to debris, mechanical damage, obstacle, the motor may spin the coupling or may non rotate at all, overheating & shutting downwardly | Inspect the blower assembly for obstruction, free spinning, and repair |

| Undersized electric motor | Load requirements exceed the motor horsepower Hp nameplate ratings. [Unlikely on manufactory-assembled heating or air workout organization just possible if someone performing a repair substituted a lower Hp motor]. | Using an Amp probe ammeter bank check the current draw of the motor against its nameplate rating. If the bodily current describe when the motor is running exceeds the rated run-amps by more than 10% and if in that location is no binding or misalignment in the organisation we suspect that the motor is under-sized. See TEST EQUIPMENT, ELECTRICAL GUIDE - separate commodity |

| Bad coupling | Jammed or defective coupling between motor and driven components; improper belt tensioning on belt-driven components | Usually a bad coupling inside the oil burner will fail by becoming loose and merely spinning, so the motor runs but the driven components practice not spin or spin at a too-low speed. But a aptitude, damaged, or jammed coupling might overheat a motor - OPINION - Ed. |

| Electric Motor Lubrication Failure | If the electric motor is a model that requires periodic lubrication and is not properly maintained its bulldoze shaft or bearings may run dry, causing binding and overheating. | Inspect the motor to decide if information technology is a model that requires lubrication. Check its maintenance history; cheque for shaft binding; lubricate the motor if appropriate; check motor drive shaft and bearings for excessive side play, wear, or looseness. Watch out: do not try to lubricate an electric motor that does not have lubrication fittings. Details are at ELECTRIC MOTOR LUBRICATION SPECIFICATIONS |

Notes to the tabular array to a higher place

Adjusted & expanded from Beckett (1989)[1]

For complete electric motor diagnostic procedures

see ELECTRIC MOTOR DIAGNOSTIC GUIDE - carve up article

Full general advice: Electrical Tests to Check HVAC Blower Fan Motor or Outdoor Compressor Fan Motor Winding on Heating or Cooling Equipment or on Other Electrical Motors

If your electric motor won't outset, vibrates or is noisy, see our diagnostic guide to problems with electric motors

at Electrical MOTOR DIAGNOSTIC GUIDE.

Air workout & Oestrus Pump Compressors & Other Motors

See

- BURNED-OUT COMPRESSOR

- CAPACITOR TYPES, for MOTORS

- CAPACITORS for HARD STARTING MOTORS

Heating arrangement reset switches: If you are looking for the main oil burner reset buttonOn heating equipment you'll want to see:

- Aquastat Functions and Cad Prison cell Relay Switch Flame Sensors (hot water boilers and some water heaters),

- STACK RELAY SWITCH On older oil fired boilers and furnaces,

- FLUE GAS SPILL SWITCH TRIPPING & RESET (gas fired equipment), and

- Depression H2o CUTOFF CONTROLS On steam heating systems.

Controls on well pumps and water supply equipment that may crave reset or repair are discussed at

- CONTROLS & SWITCHES on H2o TANKS.

- WATER PUMP PROTECTION SWITCH

And see CAPACITORS for Difficult STARTING MOTORS for advice on calculation or replacing a start/run capacitor for an electric motor that has trouble starting.

See USING DMMs VOMs SAFELY. Example: testing a blower fan motor winding: referring to the electrical diagram for your equipment, unplug electrical connectors at the fan motor. Mensurate the resistance betwixt each lead wire with a multimeter or VOM. The multimeter should exist ready in the X1 range. For accuracy, don't measure when the fan motor is hot, allow it to cool off.

When the resistance between each lead wire are those listed in the specifications for your equipment the fan motor should be normal. Zero resistance or infinite resistance are indicators of a problem.

Thermal Overload Switch Replacement

Question: how do I featherbed or replace the OL switch on this Marathon electric motor?

Question: how do I featherbed or replace the OL switch on this Marathon electric motor?

2018/06/25 hbirdkeeper said:

The thermal overload button is not skillful on my gild marathon motor tin someone delight walk me through how to wire it in featherbed it or what I could use as a substitute because the parts place said I'll be 10 weeks to order.

This is the photo of the info on this is the photograph of the info on the motor

I am a girl and don't know the technical terms just I'm non afraid to endeavour and set

[Click to overstate any epitome]

Photo from reader: data tag on a one 1/2hp Marathon general purpose electric motor capable of 115 / 208-250VAC performance

Reply: steps in replacing a thermal overload switch in a modest electric motor

Bird

Small-scale electric motor thermal overload reset switch bypass, external switch or replacement

Offset off is to avoid getting shocked or killed, so never work on equipment with power-on.

At this website you can encounter DMMs VOMs Condom Use OF inspectapedia.com/electric/DMM_VOM_Safety.php

Keep in mind that when you're not trained you don't fifty-fifty know what you don't know. A mistake can be fatal.

Second is to avoid starting a burn down past mis-wiring or by installing improper parts that don't provide the overheat and over-current protection that your motor manufacturer (Marathon) decided this motor requires for safe operation.

The therma/loverload switch on an electric motor is protecting confronting fire and shock, and protects both the motor and the circuit wiring from damage. It'south an important safety device as I will elaborate.

My birds ate the thermal overload switch that's why I had to go a new i the search protector is what is tripping not to switch

I was able to order another thermal overload switch and I paid a lot of money to have it overnighted just it keeps tripping

Common Causes of Thermal Overload Switch Tripping or Nuisance Tripping

Thermo swtiches or OL or overload switches are not what usually fail in an electric motor. Millions of them have been in use for decades. More oft the problem is elsewhere.

Thermo swtiches or OL or overload switches are not what usually fail in an electric motor. Millions of them have been in use for decades. More oft the problem is elsewhere.

Therefore I wouldn't presume that the trouble is the overload button or switch since the problem could equally or even more-likely be the motor itself -

Illustration: a typical AO Smith electric motor thermal overload relay switch replacement part available from the manufacturer and from electrial suppliers.

- a failed bearing or failing winding causing high current draw, overheating, tripping off

- bereft voltage to the motor

- improper wiring to the motor (undersized)

- improper motor selection for the environment (too hot)

- improper motor selection for the application (motor is mechanically overloaded or taxed across its blueprint)

- improper motor usage: motor left running much longer than the manufacturer's duty cycle, leading to overhating, or motor being constantly or too-frequently switched on and off, such as a well pump motor short cycling (oft due to a waterlogged pressure tank)

- improper motor maintenance: failure to lubricate bearings, bottleneck of ventilation ports with oily dust, sawdust, debris, exposure of the motor to water or leaks or flooding or corrosive environments, fifty-fifty mice or insects (getting into the motor)

Electrical Motor Thermal Overload Diagnostic #1:

Fifty-fifty before looking at the motor itself a technician would ostend that the right voltage is being delivered and that the excursion wires are all properly sized for the current rating of the circuit, the motor, and the circuit billow or fuse. Under-sized wires or low voltage can crusade circuit or motor overheating and overload tripping.

Electric Motor Thermal Overload Diagnostic #two:

Inspet the motor for debris clogging the motor'due south air vent openings. Cleaning these and the motor may fix a thermal overload tripping problem.

Electric Motor Thermal Overload Diagnostic #three:

When the motor has cooled downwards y'all can't reset the push button so the problem could be the switch itself. Try turning ability off and letting the motor absurd to room temperature, and then see if the switch will re-set.

Electric Motor Thermal Overload Diagnostic #iv:

With power off and the motor disconnected from whatever the motor drives, does the motor shaft spin easily? If not the bearings may be shot or the stator/commutator binding - the motor is shot or at the very least would demand to exist rebuilt.

(For a typical 1 - 1/two hp conventional electrical motor a motor repair shop can do that but compare the repair price confronting the cost of a new motor).

Electrical Motor Thermal Overload Diagnostic #five:

Fifty-fifty if the motor spins easily, is there whatsoever end play or wobble if you endeavour to wiggle the motor'south output shaft side to side? If so the bearing is probably shot - same every bit above.

Electric Motor Thermal Overload Diagnostic #6:

An electrician or technician trained in motor repair might remove the temperature/overload sensor switch and bound its switched wires together, so connect the motor to power.

Then she might measure the current depict and confirm that the proper voltage is being delivered. If the motor runs she would then order the proper OEM repalcement sensor switch/relay.

In other words, don't buy a repalcement switch to stick into a bad motor: you're thowing good coin after bad and you're doing something dangerous.

External motor overload switches - OL switches do not include thermal protection

There are external overload switches that tin be wired into a motor circuit.

That switch would monitor current draw (amps) and properly sized for the motor's specifications information technology could turn off the motor if the current describe is excessive - every bit can happen with a bad begetting or motor overloading.

Use the OEM Thermal Overload Switch

Aye, you could simply notice the switch inside the motor, remove it, tie together the wires that it disconnects to turn off the motor, and the motor might "run" simply information technology would be dangerous.

Watch out: yet when the motor manufacturer put in a *thermal* overload protection device their engineers decided that the motor needed protection not but from a current overload but from overheating. If you install an external switch it will not provide that safety characteristic - you're risking a motor burn, electrical brusque, electrical arc explosion inside the motor, or a edifice burn down.

Bones Steps To Remove & Supersede an Existing Overload Switch in a Small Electric Motor

Usually the small electric motor overload switch will wait much like the replacement switch (often sold grossly over-priced) I'll show with these comments.

Get the right OEM overload switch for your motor. On your Marathon one 1/two hp general purpose electrical motor's data tag there may be thermal protection switch specifications or data. Your motor includes: Thermally Protected, C0074820 051011 - those may be the OL specs only I'm not ssure - y'all'd need to ostend that with Marathon or with your electrial supplier.

Your motor's OL probably looks much like the AO Smith OL switch photo I'll attach, but of form it could differ. In other appliances and motors OL switches expect quite dissimilar. For case in a dishwasher the OL may exist a white plastic strip with ii wires connected to it.

By removing the motor's stop-cap - the end opposite the motor'due south output drive shaft you'll see several internal parts including an overload switch that will look much like our example beneath.

When you take the proper thermal/overload protection switch replacement function - MATCHING the specifications gear up by the manufacturer for your specific motor - it will ordinarily wire upwards with the same wire colour codes as the existing switch.

The technician trained to practice this job would locate the original switch, note its wire connections by switch terminal ID and color code, and lucifer the new switch to the old 1'due south connections.

Watch out: before touching anything in the motor

- electrical power is off

- electrical wires to the motor are removed

- the motor is removed from its mountain on the equipment it serves

- the motor'south end cap encompass is removed (don't remember this is always trivial)

- the motor capacitor(s) will accept been discharged to avoid getting a nasty shock

Spotter out: even this step is very dangerous. Discharging a capacitor past shorting its terminals using an insulated screwdriver tin on some occasions blow upwards the capacitor injuring anyone nearby.

Standing:

- to remove and replace the overload switch you may accept to remove the capacitor and you may have to remove a small

circuit board or "concluding board" in the motor to betrayal the wires and their connections.

Some de-soldering and soldering might exist required simply usually the wires connect with push-on spade connectors.

Yous might need to re-employ some connectors to install the replacement overload switch.

- the OEM replacement switch connections are made to match those of the switch removed and the motor is re-assembled

- the motor is demote tested every bit we described earlier earlier it's returned to use.

Sources & Reading on Thermal Overload Switches

- Marathon Electric Motors, Power Transmission Specialties, 803 Sorensen Ave. Santa Iron Springs, Ca 90670 USA Tel:

(888) 459-0115 Email: Sales@Marathon-Motors.com Website: www.marathon-motors.co - Edvard, The Basics of Built-In Motor Protection for WEngineers Beginners, 15 May 2015, retrieved 2018/06/25, original source: electrical-engineering-portal.com/basics-of-built-in-motor-protection-for-beginners

- [14] Typical Deep Well 2 Line Jet Pump Installation, Grove Electric, Chiliad&Yard Electric & Plumbing, 1900 NE 78th St., Suite 101, Vancouver WA 98665 www.grovelectric.com - web search -seven/fifteen/2010 original source: http://www.groverelectric.com/howto/38_Typical%20Jet%20Pump%20Installation.pdf

- LIMIT SWITCH TECHNICAL GUIDE [PDF] from Abzil Due north America https://us.azbil.comhttps://inspectapedia.com/electric/Limit-Switch-Technical-Guide-azbil.com.pdf retrieved 2018/05/09 original source http://u.s..azbil.com/CP-GC1003E_Vol.1_a_c/D/TEC_LIMIT_SWITCHES.pdf

- Farrell, W. H. "Motor overload protection for domestic appliances." Electric Engineering science 72.8 (1953): 694-696.

- Brighton, Robert J., and Prashant Due north. Ranade. "Why overload relays exercise non ever protect motors." Industry Applications, IEEE Transactions on 6 (1982): 691-697.

- Goba, F. August. "Bibliography on thermal aging of electric insulation." Electrical Insulation, IEEE Transactions on 2 (1969): 31-58.

- Herman, C. J. "Motor insulation life equally measured by accelerated tests and dielectric fatigue." Electric Engineering 73.i (1954): 33-37.

- Courtin, John J. "New NEMA Rerating of AC Motors." Industry and General Applications, IEEE Transactions on 5 (1965): 320-324.

Reader Q&A - also see the FAQs serial linked-to below

On 2020-08-13 by (mod) how to test an electric motor overload switch or thermal switch

Alfred:

Sentry out: if y'all are non trained in safe electric piece of work and procedures y'all could exist shocked or killed when working on electrical equipment. That warning said

With the switch removed from the motor,

Use a DMM or VOM to exam the overload switch as follows:

Set the DMM/VOM to OHMS and to the most-sensitive or 1 Ohm or Rx1 setting or switch position

How to Test a ii-Wire Thermal Overload Switch:

Connect the DMM/VOM leads to the 2 wires of the switch;

Read the resistance on the ohms scale: you lot should see zip resistance or very close to 0 ohms.

If the switch is showing i ohm or higher resistance it should exist replaced.

How to Test a iii-wire Thermal Overload Switch:

Some thermal overload switches such equally used on pool pumps and 3 phase motors accept iii wires or connections. In a 3-last thermal overload switch, each heater is wired in serial with i of the phase windings of the electrical motor that it is protecting.

If the disc overheats it snaps "open up" thus opening the neutral wire to plough the motor off. Dual -voltatge electric motors typically tin can yet utilize a single thermal overload device.

In this case

Connect the DMM/VOM leads kickoff to terminals #i & #2: resistance should exist 0 or very close to 0 ohms.

So connect the DMM/VOM leads to terminals #two & #three: resistance should exist 0 or very close to 0 ohms.

If either of these tests shows resistance more than 1 ohm of resistance, then supercede the switch.

More details are in the article starting at ELECTRIC MOTOR OVERLOAD RESET

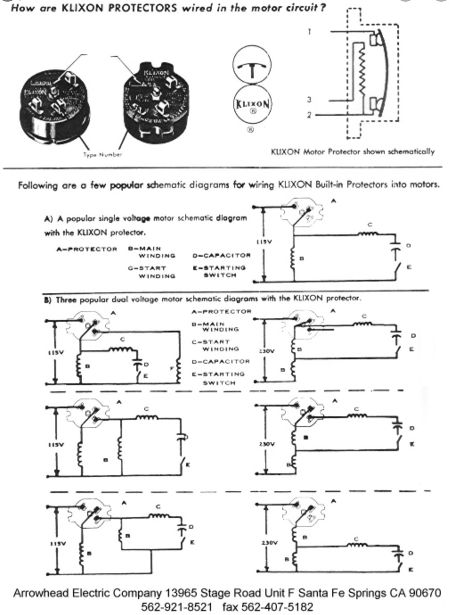

Shown above: a Klixon thermal switch No. 10370140 with three terminals.

Klixon also provides 6-last high-chapters thermal overload switches.

Beneath is a data sheet, courtesy of Arrowhead Electric, showing typical wiring diagrams for this type of 3-final Klixon overload protector switch.

[Click to enlarge whatever image]

Arrowhead Electric is an electrical contractor in Santa Fe Springs CA; the company tin exist contacted at https://arrowhead-electric.com

How practise I examination a 3 wire overload swtich

Allow the motor absurd, then information technology shouldbe possible to button in the crimson reset button

We are looking for the reset button it is a Klixon

CGJ36CD

Swoop

A thermal overload protector or reset button might "wear out" just I suspect some other problem lurking here. Repeated operation at depression voltage can damage some electric motors.

A service tech will often shotgun the diagnosis by simply replacing the starting capacitor to see what happens - that's cheap.

An experienced service tech can check out the compressor motor itself, for example by measuring its current draw and comparison that to normal.

We have a 2hp motor on an air compressor that was initially wired with too small-scale of wires. There's something like 300' of wire betwixt the breaker and the compressor. The compressor ran, but repeatedly tripped the thermal overload. Afterwards being used in this condition for a few weeks, with multiple resets, the electrician re-wired to 240v. Recently, the compressor started tripping the thermal overload on the motor on a regular basis. When first put in service with the undersized wire, the cherry button was reset 5 or ten times. In the last few months, mayhap a few more times. Now it'due south tripping every few days. The compressor was run quite often the first month, but at present just a few times a day for a few minutes. Do the thermal overload switches fully protect the motor? How probable is it that the first few weeks with the undersized wires damaged the motor? Exercise the red push, thermal overloads 'wear out'? Tin can an electrician make up one's mind if it's the motor or the thermal protection that needs replacement?

Not necessarily, Robert; a broken winding may not open until at higher motor speed.

If it is a winding that opens would information technology react the aforementioned on both speeds?

A winding that opens as the motor gets up to speed

a failing motor bearing

a bad internal centrifugal switch in the motor

I have a 2 speed ane-1/2hp pump motor unmarried phase 240 volt capacitator get-go capacitator run. It was tripping the billow when starting. I thought information technology was the run capacitator and replaced it. At present it volition tries to start just quits before it gets up to full speed. It no longer trips the breaker. What would exist causing this?

Thanks, I am an electrician but not a motor person. Hate to junk it simply motor shops don't want to mess with this pocket-size of a motor.

I tin can only guess but information technology sounds to me as if the motor is failing under load.

My iii hp air compressor electric motor starts and builds pressure to about 25 to 30 lbs and then the billow trips on the motor, then about xv to xx secs it resets. I push button the push on the billow and it starts. Then the same matter happens again. What practise you think maybe billow or motor or something else? Thank you. Kenny

The condenser fan won't accident when the dryer wire is connected, but when disconnected it will blow. delight what is the solution? cheers.

Mike

Is there a reset button on a Hobart Dishwasher or how exercise you lot re-fix the unit?

An authoritative answer from Hobart was not easy to observe, though you might become help from the manual for your Hobart dishwasher.

I have not found a reset push.

Nearly dishwasher controls re-set by turning the control punch through its operating positions back to OFF - open the door and then re-latch information technology.

However a temperature sensor could be tripping off the dishwasher - try cleaning the sensor in the dishwasher - scrub with vinegar and a scrubby sponge - as that may fix the problem.

Is at that place a transmission reset push button on a Hobart 474837-00001 dishwasher motor

...

Keep reading at Electrical MOTOR OFF on RESET or select a topic from the closely-related articles below, or come across the consummate ARTICLE Index.

Or see Electric MOTOR OVERLOAD RESET FAQs - questions & answers posted originally at this article

Or run across

CAPACITORS for Difficult STARTING MOTORS for communication on adding or replacing a commencement/run capacitor for an electric motor that has trouble starting.

Electric MOTOR DIAGNOSTIC GUIDE

ELECTRIC MOTOR WIRING DIAGRAMS & GUIDES

Suggested citation for this web folio

Electric MOTOR OVERLOAD RESET at InspectApedia.com - online encyclopedia of edifice & environmental inspection, testing, diagnosis, repair, & problem prevention communication.

Or come across this

Index to RELATED Articles: Article INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX institute below to Enquire a Question or Search InspectApedia

...

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box beneath and nosotros will answer promptly.

Search the InspectApedia website

Note: appearance of your Comment below may exist delayed: if your annotate contains an image, web link, or text that looks to the software every bit if it might be a web link, your posting will appear afterward it has been approved past a moderator. Apologies for the filibuster.

Technical Reviewers & References

Click to Show or Hibernate Citations & References

Publisher InspectApedia.com - Daniel Friedman

Source: https://inspectapedia.com/electric/Motor_Reset_Button.php

0 Response to "what drive units are being used in 2018 to replace bad drive units in model s"

Post a Comment